Application of threaded fasteners in automobile assembly

A threaded fastener connection is one of the commonly used connection mode, including welding, riveting and viscose connection screw fastener connection. Its purpose is to make the parts are connected tightly, and under the external force, with high precision, convenient assembly and disassembly and convenient parts.

Threaded connection force 4, tensile stress, shear stress, tensile stress and bending stress, tension and bending stress shear stress. If you want to ensure the threaded fasteners connected by connecting parts can overcome by static or dynamic external force, threaded fasteners to be connected components to produce an axial clamping force, the clamping force provided by the applied torque. To overcome the friction and press the bolt and bolt are connected parts of the rigid relations than elastic deformation, so as to form a clamping force in the bolt joint surface between both ends. The correct tightening process should control the clamping force, so the assembly is the essence of the axial bolt clamping force control in the appropriate range.

The threaded fastener connection assembly process, the influence of clamping force dispersion by the selected method of assembly and other external conditions. In the assembly, the clamping force must be large enough to ensure reliable connected parts can be fit in the work process, no relative movement; on the other hand, the clamping force applied we must ensure that the bolts and connecting parts are not damaged or plastic deformation in the assembly and service process. According to the market survey, have connections in the vast majority of issues, such as bolts loosening, fracture, connected parts indentation, destruction, are due to clamping force is not accurate or inaccurate result. Research shows that the axial bolt clamping force is bigger, the anti loosening and anti fatigue performance better, usually use bolt tightening to yield the best effect.

At present in the automotive assembly site, considering the actual production cycle and operation, can not correctly measure each bolt clamping force side, so the torque can be as intermediate value to evaluate the bolt assembly quality. On the side of torque control, torque control precision and tighten the process of tightening tools are two key. Under the condition of torque control accuracy of pneumatic tool is 10% ~ 40%; manual fixed torque spanner precision is about 10%; electric tightening machine torque control precision can reach 3% ~ 5%. which tightening tools and torque control precision directly determines the assembly level.

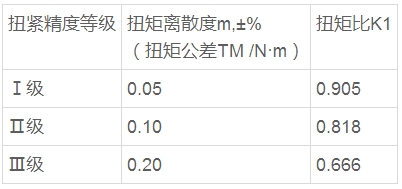

The domestic automobile industry standard QC/T518-2013 automotive fasteners tightening accuracy of thread fastener torque will be divided into 3 grades, grade I, II, III, different levels of the corresponding precision tolerances and tightening torque torque ratio is shown in table 1.

Table 1 different grades of tightening torque than the corresponding precision

Table 1 different grades of tightening torque than the corresponding precision

Application of threaded fasteners in automobile assembly

Note: minimum value of K1= fastening torque / maximum value of fastening torque

In the 10.9 stage of friction coefficient of 0.12 M20X1.5X100 six angle bolts as an example, the class III assembly, target fastening torque, and the torque fluctuation range, clamping force made thread is minimum, the goal of improving the fastening torque and improve the assembly level, and the torque range becomes smaller, the clamping force is improved. The target torque assembly the ratio of grade III assembly increased by 0.087% and the clamping force on the thread to improve 32.5%. according to the foreign standard threaded fastener assembly, when threaded connection level III, if the bolt using M16 can meet the use requirements; when choosing the class I assembly, bolt specifications can be reduced to M12. of thread fastener assembly classification is necessary. Fastener supplier orders, should first consider the technical agreement requirement, compared to the grade and the grade of assembly, assembly, target bolt tightening torque The torque fluctuation range is reduced, and the clamping force on the bolt is increased; when the clamping force of the connecting structure to the bolt is not required, the assembly of the first stage can reduce the bolt size, realize the lightweight weight reduction, and make the structure compact